Audi claims first synthetic gasoline made from plants

This article by Eric Mack for GizMag may be of interest to subscribers. Here is a section:

In late 2014, Global Bioenergies started up the fermentation unit for a pilot program to produce gaseous isobutane from renewable biomass sugars such as corn-derived glucose. Gaseous isobutane is a sort of raw material for the petrochemical industry that can then be refined into a variety of plastics, fuels and other applications.

The next step in the process was to run the material through a conditioning and purification process, allowing it to be collected and stored in liquid form under pressure. Some of it was then sent to Germany to be converted into isooctane fuel, creating a pure, 100 octane gasoline.

"To me this is a historic moment," says Global Bioenergies CEO Marc Delcourt. "It is the first time that we have produced real gasoline from plants."?Isooctane is currently used as an additive to improve fuel quality, but could also be used a stand-alone fuel. Audi calls the final, refined form of the fuel "e-benzin" and claims that it burns clean due to its lack of sulfur and benzene. Also, its high grade enables it to power engines using high compression ratios for more efficiency.

Audi will test the fuel composition and conduct engine tests to see how it performs before eventually trying it out in vehicle fleets. Delcourt says he could see it being used in consumer cars on a large scale "very soon."

"We thinking we're bringing green-ness to a field that desperately needs green-ness," says Rick Bockrath, vice president for chemical engineering at Global Bioenergies. "It's basically how we're moving away from an oil-based economy towards something that has a renewable, sustainable future to it."

This follows a story from a month ago talking about how Audi produced a diesel fuel from air and water through a chemical process. Today’s story is a further iteration of this concept.

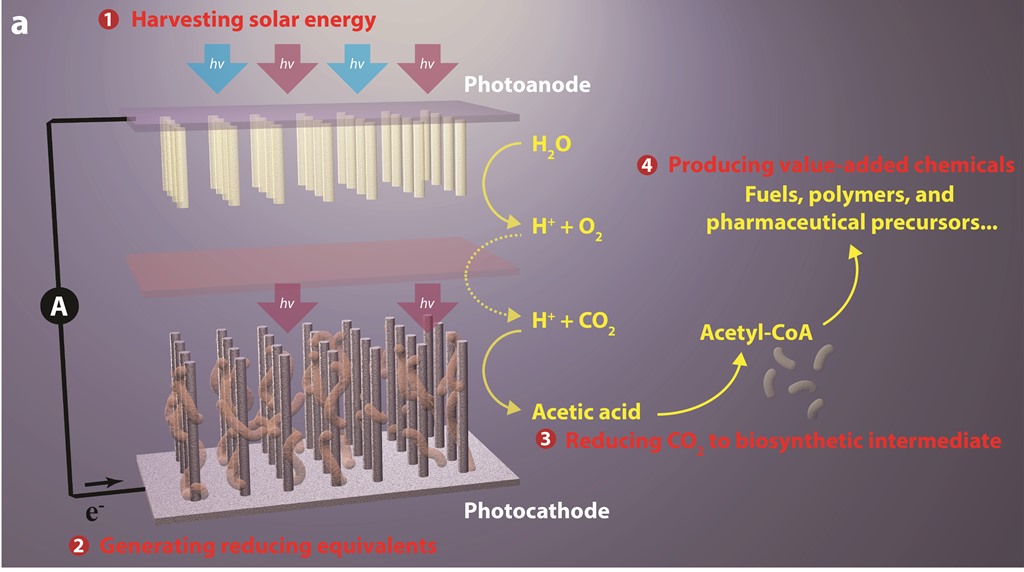

In the last month we have also learned that artificial photosynthesis has been achieved. Here is a section from an article by Lynn Yarris for Lawrence Berkeley National Lab:

Scientists with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) and the University of California (UC) Berkeley have created a hybrid system of semiconducting nanowires and bacteria that mimics the natural photosynthetic process by which plants use the energy in sunlight to synthesize carbohydrates from carbon dioxide and water. However, this new artificial photosynthetic system synthesizes the combination of carbon dioxide and water into acetate, the most common building block today for biosynthesis.

“We believe our system is a revolutionary leap forward in the field of artificial photosynthesis,” says Peidong Yang, a chemist with Berkeley Lab’s Materials Sciences Division and one of the leaders of this study. “Our system has the potential to fundamentally change the chemical and oil industry in that we can produce chemicals and fuels in a totally renewable way, rather than extracting them from deep below the ground.”

When you start to put the pieces together we are quickly moving into an era when biomass takes on a completely new dimension. Creating hydrocarbons from carbon dioxide, sunlight and water in meaningful quantities is still a long way off but the proof of concept is real and pace of technological innovation continues to accelerate. It is for this reason that Toyota for example has taken such a big bet on hydrogen fuel cells. They believe the issues with availability of the fuel are going to be solved.

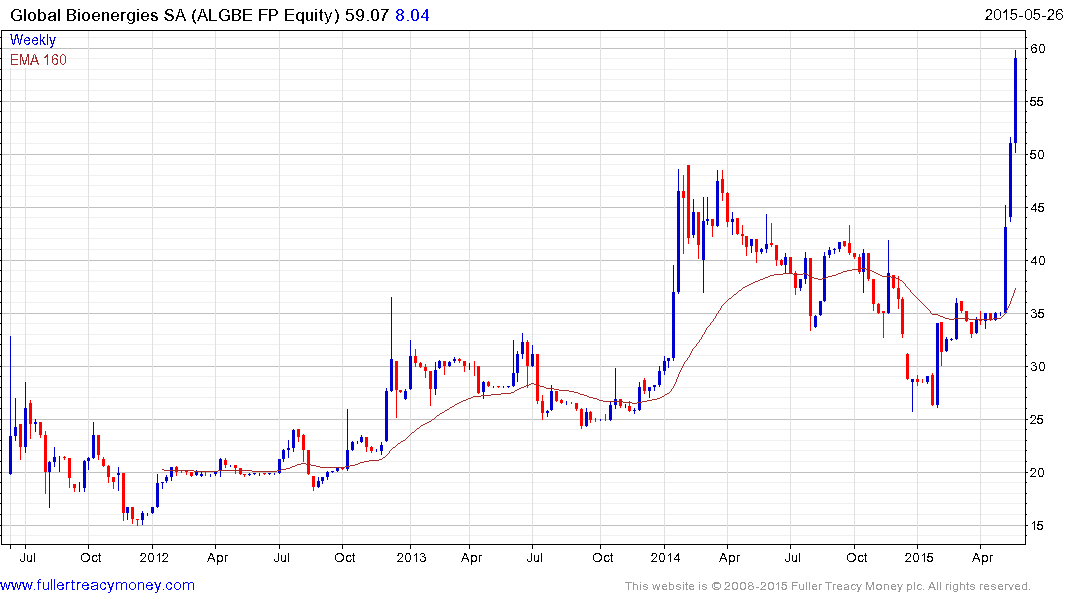

France listed Global Bioenergies has a market cap of €163 million following a doubling of the share price in the last three weeks. The first clear downward dynamic is likely to signal mean reversion is underway.